Introduction to the power module industry

1. What is meant by power module

Power modules, also known as modular power supplies, are power supplies that can be mounted directly on a printed circuit board to provide power for application-specific integrated circuits (ASICs), digital signal processors (DSPs), microprocessors, memories, field-programmable gate arrays (FPGAs), and other digital or analog loads. Generally, these modules are referred to as point-of-load (POL) power supply systems or point-of-use power supply systems (PUPS). Because of the obvious advantages of the modular structure, modular power supplies are widely used in switching equipment, access equipment, mobile communications, microwave communications, as well as optical transmission, routers, and other communications fields, and in various industries such as automotive electronics and aerospace.

2.Modular power supply features

(1) Simple design: only a power supply module, with a small number of discrete components, you can get power.

(2) shorten the development cycle: modular power supply is generally available in a variety of input and output options. Users can also repeat the iteration or cross iteration, constituting a combination of building block type power supply, to achieve multiple inputs and outputs, greatly reducing the prototype development time.

(3) Flexible changes: product design needs to be changed, just convert or parallel another suitable power supply module can be.

(4) low technical requirements: modular power supply is generally equipped with standardized front-end, highly integrated power supply module and other components, thus making the power supply design more simple.

(5) Modular power supply shell has a collector, heat sink and shell of the trinity of structural forms, the realization of the module power supply conduction cooling method, so that the power supply temperature value tends to minimize the value. At the same time, but also gives the module power supply normative packaging.

(6) high quality and reliability: modular power supply are generally used in fully automated production, and with high-tech production technology, so the quality is stable and reliable.

(7) Wide range of applications: modular power supply can be widely used in aerospace, locomotives and ships, military industry and weapons, power generation and distribution, post and telecommunications, metallurgy and mining, automatic control, household appliances, instruments and scientific research and experimentation and other social production and life in various fields, especially in the field of high-reliability and high-tech plays an irreplaceable important role.

3. Power module internal disassembly

DC/DC module power supply is a widely used secondary power supply in the design of electronic products, it will be a single output voltage of the primary power supply for the secondary conversion, into a variety of required voltage, provided to the chip. Due to the small size of the module, so the power density requirements are high, while the working environment is more harsh, high reliability requirements; module power supply general requirements for the operating temperature of - 20 ~ 55 ℃, MTBF (Mean Time Between Failure) requirements in the 200,000 hours or more.

UC3843 module power supply, for example, it is a high-performance fixed-frequency current-mode controller, designed for DC to DC converter low-voltage applications, designers only need to use a small number of external components to obtain cost-effective solutions.

The UC3843 features automatic feed-forward compensation, latching pulse-width modulation, under-voltage lockout, low-voltage startup, and current-mode operation up to 500kHz. The device is available in an 8-pin, dual in-line plastic package and a 14-pin, plastic surface-mount package (SO- 14).

UC3843 power module internal structure by the UC3843 by the oscillator, error amplifier, current detection comparator, pulse width modulation latch, reference regulator and other components.

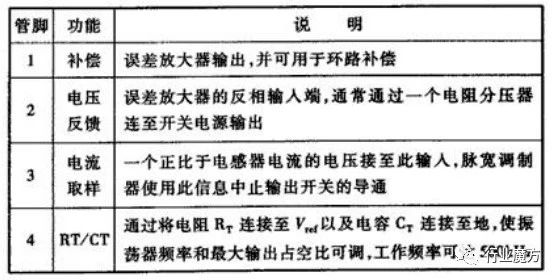

UC3843 chip pinout description (dual in-line package):

4.Power module classification

1) Green Power Module

Green power supply refers to the green computer related to efficient power saving power supply, according to the U.S. Environmental Protection Agency on June 17, 1992 “Energy Star” program, desktop personal computers or related peripherals, in the sleep state of the power consumption of less than 30 watts, in line with the requirements of the green computer to improve power efficiency is to reduce power consumption. Improving power supply efficiency is a fundamental way to reduce power consumption. On the efficiency of 75% of the 200-watt switching power supply, the power supply itself to consume 50 watts of energy.

2) High Frequency Switching

Because of the communication equipment used in a variety of integrated circuits, the power supply voltage is also different, in the communication power supply system using high power density of high-frequency DC-DC isolation module power supply, from the intermediate bus voltage (generally 48V DC) into a variety of DC voltage required, so that you can greatly reduce the loss, easy maintenance, and installation, increase is very convenient. Generally can be installed directly on the standard control board, the secondary power supply requirements are high power density. Due to the increasing communication capacity, communication power supply capacity will continue to increase.

(3) (DC/DC) converter

DC/DC converter will be a fixed DC voltage into a variable DC voltage, this technology is widely used in trolley buses, subway trains, electric vehicles, stepless speed and control, at the same time to make the above control to accelerate the smooth, fast response performance, and at the same time to receive the effect of saving power.

(4) Uninterruptible power supply (UPS)

Uninterruptible power supply (UPS) is a highly reliable, high-performance power supply for computers, communication systems and the requirement to provide uninterrupted occasions. AC utility input through the rectifier into DC, part of the energy to the battery charging, the other part of the energy through the inverter into AC, through the transfer switch to the load. In order to provide energy to the load when the inverter fails, another way of backup power is realized through the power conversion switch.

(5) Inverter module power supply

Inverter power supply is mainly used for frequency conversion and speed regulation of AC motors, which occupies an increasingly important position in the electrical drive system, and has gained great energy-saving effect. The main circuit of inverter power supply adopts AC-DC-AC program. Industrial frequency power supply through the rectifier into a fixed DC voltage, and then by high-power transistors or IGBT PWM high-frequency converter, the DC voltage into a reversal of the voltage, frequency variable AC output, power output waveform approximate sinusoidal waveforms, used to drive AC asynchronous motor to achieve stepless speed regulation.

6)Inverter Modular Power Supply

High-frequency inverter rectifier power supply is a new type of high-performance, high-efficiency, material-saving welding machine power supply, representing the direction of development of today's welding machine power supply. Due to the commercialization of IGBT large-capacity module, this power supply has a broader application prospects.

(7) High-voltage DC module power supply

High-voltage DC power supply is widely used in electrostatic precipitator, water quality improvement, medical X-ray machines and CT machines and other large-scale equipment. Voltage up to 50 ~ l59kV, current to 0.5A or more, power up to 100kW.

Power module production process

Power Module Industry Chain

Power Module Situation in China

1.2022 China's modular power supply in the power supply market as a percentage of the situation

Modular power supply accounted for 3% of the overall power supply market, the relative share is low, the main power supply market is still dominated by switching power supply, accounting for 56%, inverter accounted for 9%, inverter accounted for 4%, UPS power supply accounted for 4%, linear power supply accounted for 1%, and the other accounted for 24%.

2.China Modular Power Supply Production Value 2018-2025

The output value of modular power supply in China reached about 4.24 billion yuan in 2022 and is expected to reach 14.32 billion yuan in 2025.

Major Power Module Companies in China

China's modular power supply market share of each brand in 2022, Emerson accounted for 12.11%, Ericsson 7.41%, Vicor accounted for 6.41%, Ragu accounted for 5.61%, New Raynen accounted for 5.21%, synqor accounted for 5.11%, TDK accounted for 3.80%, Power-ONE dipped 4.3%, DISA accounted for 3.2%, and others accounted for 46.85%.

China's power module industry outlook

1, technically speaking, the power module will continue to pursue higher density and higher efficiency

Continuously pursue higher density and higher efficiency, the future power supply will be as modular as Lego blocks, from the front-end AC/DC to DC/DC and then to the point of load power supply will be a series of modular products.

The most important driving force of the power supply company always comes from the customer, to the base station, for example, the trend of miniaturization of the base station will have higher requirements for the power density, while the volume reduction to the power supply space reserved for the smaller; Secondly, as the SoC function is getting stronger and stronger, the current requirements are getting bigger and bigger, and the design of heat dissipation system is becoming more and more demanding. And including security cameras and other AI products for the size requirements are even more demanding. How to be able to fit FPGAs and AI modules into traditional security camera modules is a constant challenge for the power supply.

2、Future, power supply module will face the customer's constant special needs, which puts forward new requirements for the factory's product richness

With the product development is more and more rapid, the power supply factory is difficult to meet the needs of all customers through a standardized product, the customer's time is limited, how to quickly meet the customer's customized needs is MPS through mEZ want to achieve the effect. And for large companies, standardized products are still the focus of power management, so it requires both efforts at the same time.

It is also because of the specificity of each customer's needs, even the big manufacturers because of time or product development and other constraints, it is difficult to cover all the power needs, this situation has led to the layout of the power management vendors are quite decentralized.

For the future development of power modules, the future part of the field of power modules will be dominated by chip companies or passive component companies, because the chip factory or passive component factory relative to the power plant has a greater cost advantage, which is why we see more and more power chip vendors to provide a richer combination of power modules, but for high-power power supply, the traditional power supply plant still has a design advantage.

3, the future trend of power modules: more powerful and simpler.

The rapid expansion of wired and wireless networks as well as cloud computing is an important trend in front of people's eyes. This upper level of the megatrend, driven by the lower level of the hardware and its components of the development trend. The rapid climb in network throughput requires powerful and complex FPGAs, processors, etc. for performance support. This, in turn, requires high-performance, highly reliable and more powerful power modules to guarantee.

Another important trend in power modules is to simplify designs and shorten time-to-market as much as possible. This makes the top power module companies can help customers to shift the main work from the power part of the energy to the overall design of the system, as well as in addition to the power part. Size reduction is part of increasing power density and part of increasing integration. As the demand for device integration continues to increase, many new challenges are bound to be encountered, especially for power devices, where heat dissipation is critical and will affect the reliability of the device.