All kinds of electronic equipment in our lives are inseparable from the power adapter. The quality of the power line adaptor directly affects the technical performance of the electronic equipment and its work safety and reliability. When there is a problem in any part of the power adaptor, the entire product will be paralyzed, so it is particularly important to conduct a comprehensive test on the power adaptor product.

Let’s take the electric motorcycle charger as an example. As one of the four major parts of electric motorcycles (controller, charger, battery, and motor), the charger is an important part of electric motorcycles and directly affects the safety of electric motorcycles. . Inferior chargers may cause serious consequences such as electric shock, fire or even explosion. Therefore, the charger will undergo rigorous testing and certification in the stages of R&D, production, and certification. Figure 1 shows the complete testing program provided by Zhongshan Kingrong Electronics.

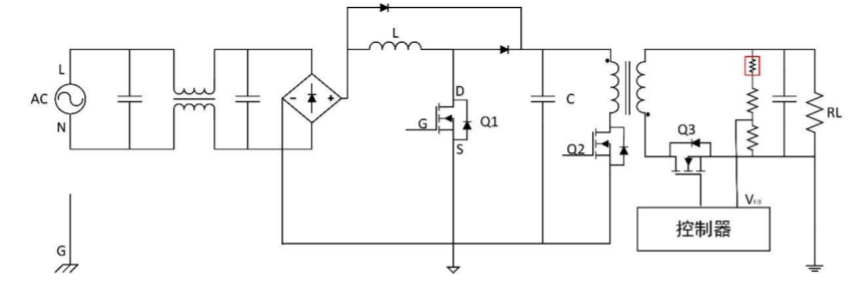

The important circuit component of the charger is the switching power adaptor, as shown in Figure 2. When the power adaptor is running for a long time, the problem of voltage and current instability will occur, and even overvoltage, undervoltage, overload, overheating, etc. may cause equipment damage. Therefore, it is necessary to strictly conduct all-round tests on the power line adaptor's input, output, abnormal working conditions, switching devices, etc., as well as endurance tests to verify the stability of the product. Today I will focus on introducing two test tools for everyone-PA power analyzer and ZDL oscilloscope recorder.

Test equipment—PA power analyzer

The PA power analyzer can accurately measure the output voltage, current, power, harmonics and conversion efficiency of the power adaptor. The Zhiyuan PA5000H power analyzer has a power measurement accuracy of 0.05%, a bandwidth of 5MHz and a wealth of harmonic measurement functions. It is widely used in the research and development and testing of power products.

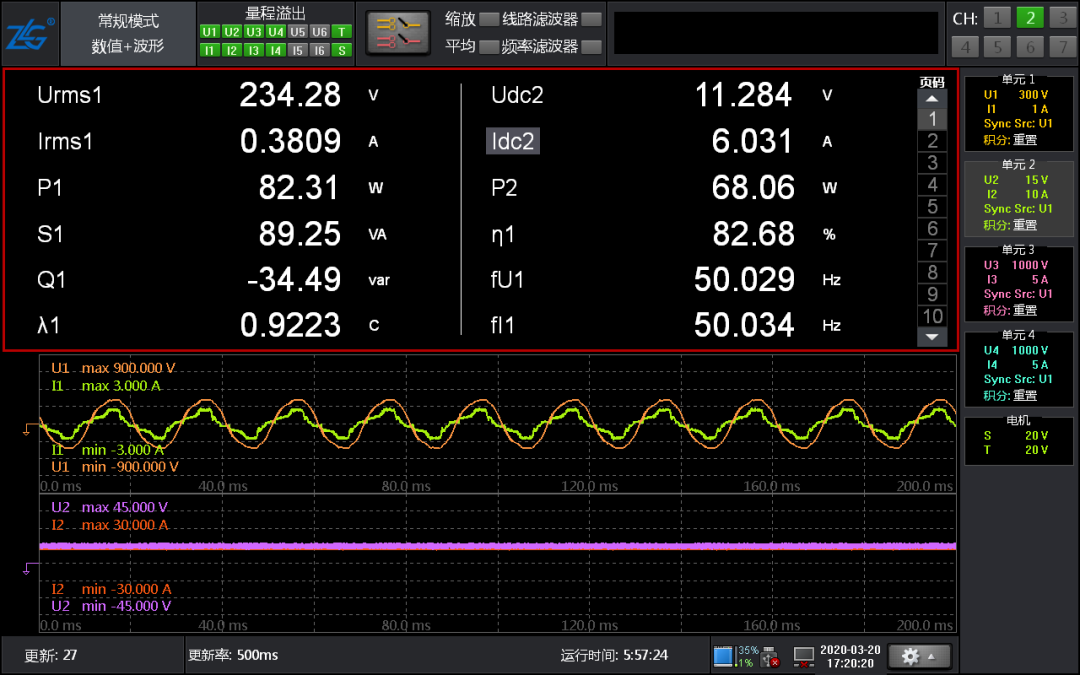

1. Power analyzer-electrical parameter test

The power analyzer focuses on steady-state testing. The power analyzer can simultaneously test AC input and DC output, analyze the overall energy efficiency and electrical parameters simultaneously, and test the input and output voltage, current, test voltage, current RMS, power factor, Efficiency, harmonics, etc., as shown in Figure 3.

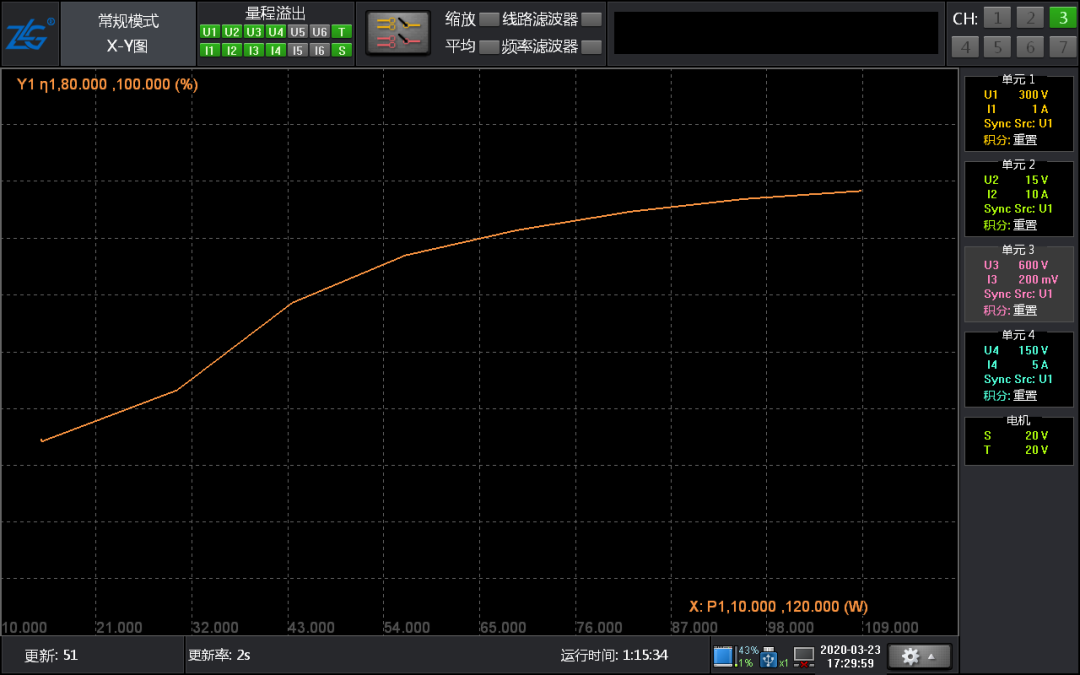

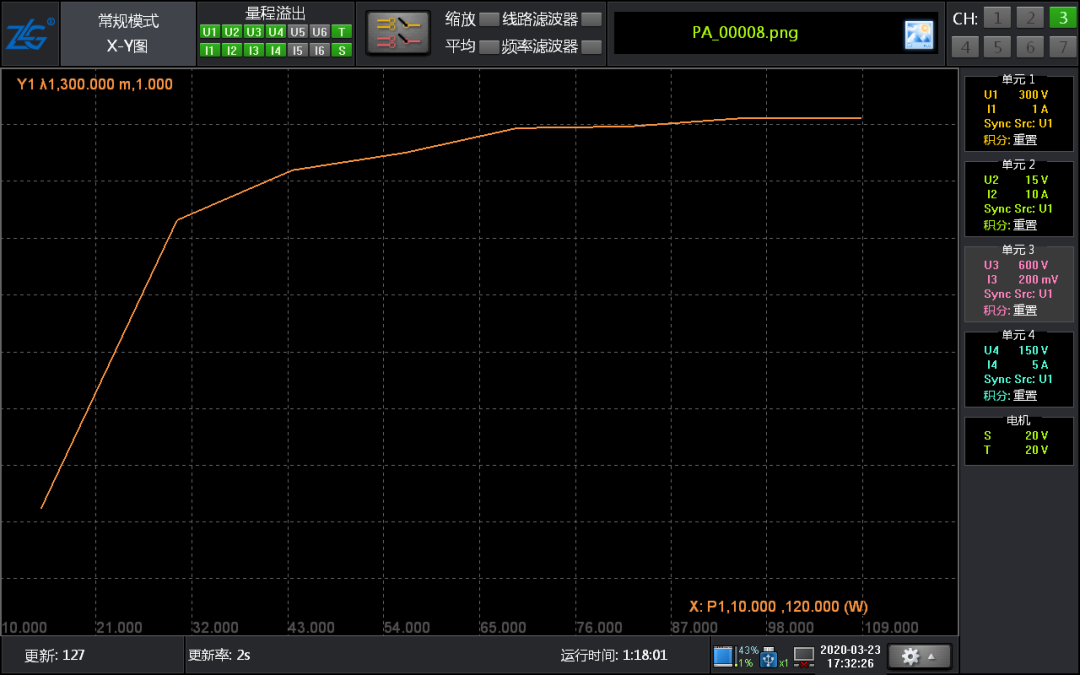

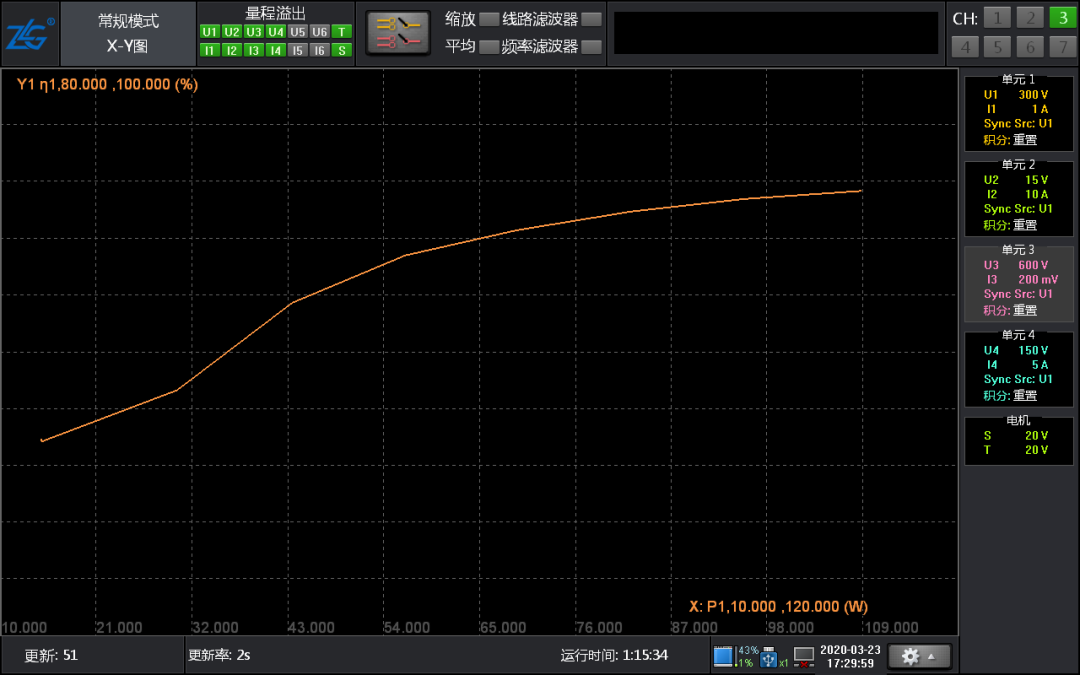

2. Power analyzer-efficiency and power factor test

The power analyzer tests the AC input power and DC output power, and sets the electronic load from no load to full load. Using the X-Y display mode of the power analyzer, you can directly test the efficiency and power factor graphs from no load to full load.

3. Power analyzer—IEC harmonic test

Electric products will be tested according to IEC61000-3-2 and IEC61000-3-11 standards to verify whether they meet the standard requirements. The PA power analyzer can measure up to 500 harmonics, and there are multiple combinations of display methods that can be displayed simultaneously. Display the content of each harmonic.

4. PA power analyzer-impulse current test

Usually, a large current is generated at the moment when the load is energized. Excessive current will affect the normal operation of the device. The PSA programmable AC power adaptor can be used to simulate the voltage conditions when the output start phase is 0°, 90° and 270°, and the PA power analyzer can be used to test the start-up impulse current of the electronic product.

Test equipment—ZDL oscilloscope recorder

The ZDL6000 oscilloscope recorder is equipped with 8 board card slots as standard, and each input channel is insulated and isolated from each other, which can save a large number of high-voltage differential probes for power users, and can provide a variety of input boards and channels such as voltage, current, temperature... Up to 128CH, providing the best solution for customers to observe waveform timing and find abnormal signals.

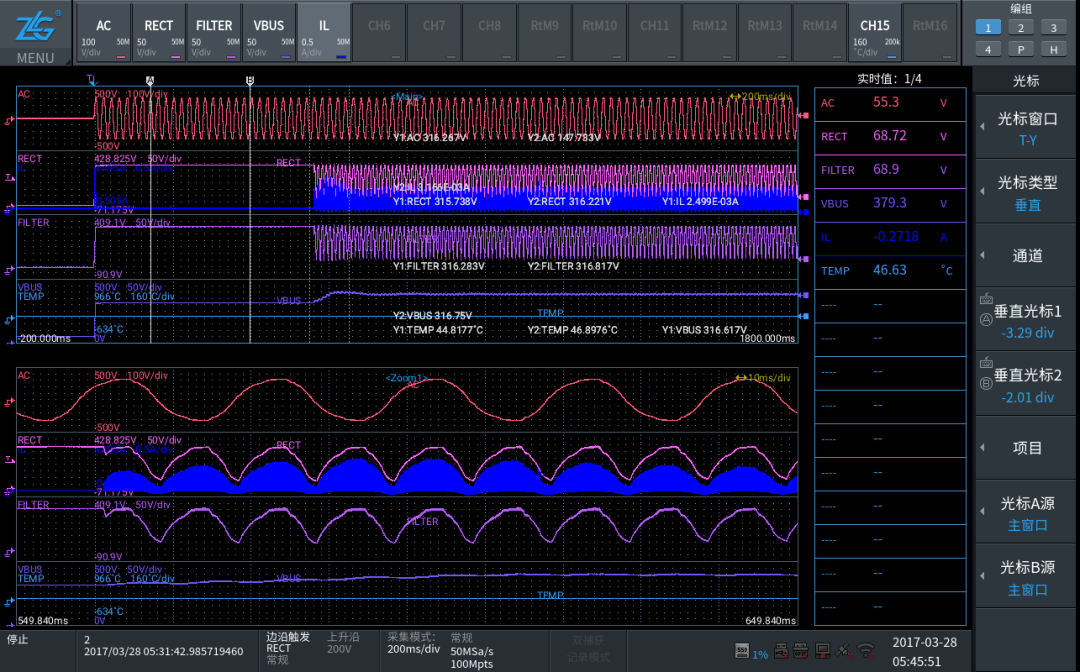

1. Oscilloscope recorder-drive timing test

The general way to test the drive sequence is to use an oscilloscope and a differential probe to test the Vgs and Vds of the MOS, and use a current probe to test the inductor current. The corresponding drive signal quality and inductor current working mode can be observed. If it is tested with an oscilloscope, There is no need for a differential probe, the test is more accurate and more convenient, as shown in Figure 8.

2. Oscilloscope recorder-abnormal capture and durability test

Abnormal capture: When the power product is running for a long time, I don't know what problems will occur. The oscilloscope cannot set the trigger conditions and it is not easy to capture anomalies. However, after using the oscilloscope to record the waveform, it can be reviewed to effectively capture the abnormal waveform;

Endurance test: Power products need frequent on/off experiments, and there may be only one failure for thousands of times, so the recorder is required to record and analyze the stability of the product for a long time.

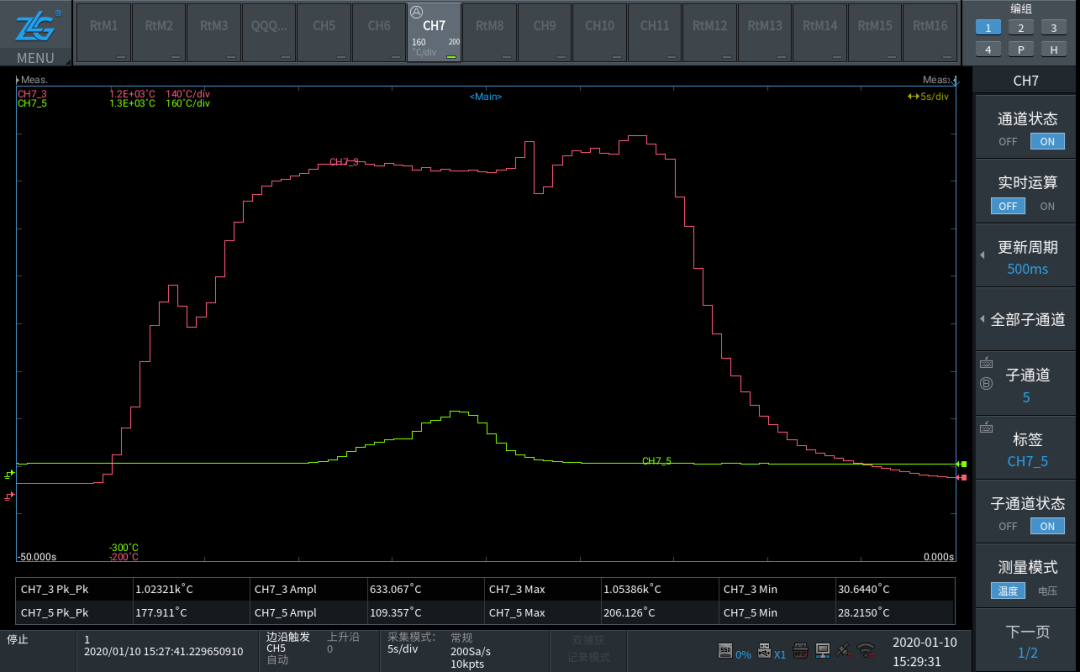

3. Component temperature rise test

Abnormal temperature in key parts of the equipment will cause equipment performance degradation or even damage. Therefore, the temperature rise test is an indispensable item in the product development process. Using ZDL6000 can flexibly combine voltage acquisition cards, 16-channel cards, temperature acquisition cards and other boards for simultaneous measurement. For example, in the temperature rise test, a 100M card and a temperature card can be assembled to simultaneously test the operating voltage, current and temperature rise of key parts of the device.

Summarize

In order to ensure the stability of the power adaptor for a long time, it is necessary to conduct a comprehensive test and analysis of the power adaptor. There will be dozens of test items. It is necessary to choose a suitable test instrument according to the test items to give full play to the maximum performance of the instrument. Power analyzers are used for energy efficiency and harmonic testing, and oscilloscope recorders are used for isolation testing, multi-channel synchronization analysis, durability testing, and abnormal capture.

Next News ▲:Awarded "Integrity Business Enterprise Certificate", AAA Grade.

Previous News ▼:THIS IS THE FIRST NEWS